Looking at the internal structure of a hard drive, it is impossible not to marvel at the feats of electronic, mechanical, electrical and, materials engineering that it encapsulates. Perhaps the precision with which an HDD operates is best exemplified by the “flying height.” It refers to the distance between the sensitive read/write heads and the magnetized platters that spin at speeds up to 15,000 rpm. This distance is typically less than 5 nanometers!

Caution: Hard drives are highly intricate devices that should not be opened outside of specialized environments known as cleanrooms. These ISO-certified environments are meticulously maintained: 300 air changes per hour and advanced HEPA filters ensure that a Class 100 cleanroom contains fewer than 100 particles larger than 0.5 microns per cubic foot of air. This is to ensure that the sensitive components such as platters remain uncontaminated. Stellar's Class 100 cleanroom is the only such controlled environment in the country.

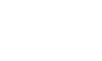

To explain the anatomy of a hard drive, we will examine a 1 TB Western Digital Internal SATA HDD.

The data stored within this device resides on the platter—the primary component responsible for holding information.

1. Platter

The platter is the shiny disc you see in the image above. This disk is usually made of aluminum, glass, or ceramic. Glass offers better surface flatness, and hence, tinier HDDs—such as those used in laptops—have platters made of glass. They have to be buffed so that the surface roughness is less than 1 Angstrom (10-10 m). The platters are then coated with an adhesion under-layer and multiple nanometer-thick layers of non-magnetic and magnetic alloys. Finally, a carbon-based overcoat and a thin lubricant film are deposited for better durability.

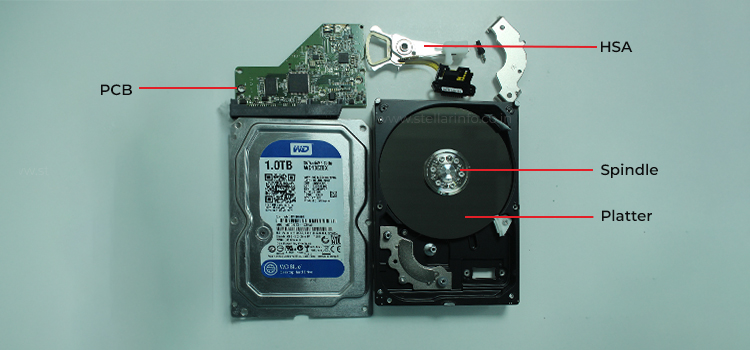

Let's now understand how data is organized on the platter. For that, we need to understand four terms: tracks, cylinders, sectors, and domains.

- Tracks are concentric circles on the surface of the platter.

- Sectors are subdivisions of a track, and each sector stores a fixed amount of data.

- Magnetic domains are subdivisions of tracks; each domain represents a unit of binary data (zeros and ones).

- Cylinders are vertical arrangements of tracks across multiple platters.

Between the platters are dampers or separators which reduce air fluctuations and acoustic noise.

As previously mentioned, hard drives should only be opened in a Class 100 cleanroom to prevent contamination and damage to their sensitive components. The platters are very vulnerable, so even if one speck of dust, dander, etc. (whose typical size is 1–250 micron) settles on it, the platter could end up getting scratched during operation. This can render the hard drive dysfunctional and you could end up losing access to the data stored in it.

However, the platter is not the only vulnerable component in an HDD. The head stack assembly, which carries the read/write heads, is even more delicate.

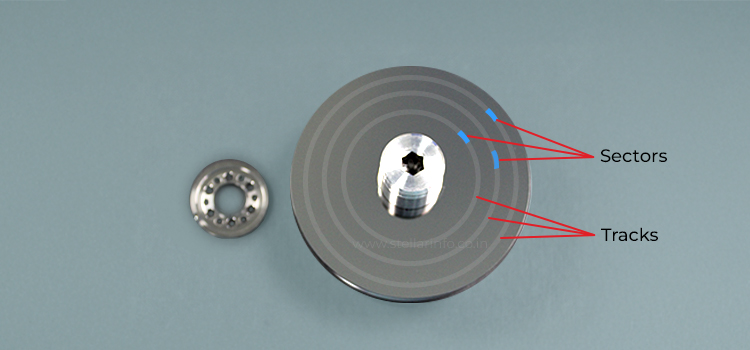

2. Head Stack Assembly (HSA)

The Head Stack Assembly (HSA), shown below, is the key part that facilitates the read/write heads to store (and access) information on the platters.

Now let's understand how the Head Stack Assembly (HSA) works.

The HSA is responsible for positioning and moving the read-write heads over the platters. This ensures precise alignment so that the data is read from or written on the correct sector of the platter.

The HSA has arms (long metal pieces) to support the heads, a Flexible Printed Circuit (FPC) that connects the HSA to the PCB and transmits electrical signals, a Voice Coil Motor (VCM) that drives the HSA's movement, and sliders and heads which are the actual data reading and writing mechanisms.

To fully understand its operation, we must take a closer look at the read/write head and its intricate design.

The read-write head is a tiny device located at the tip of the slider, which interacts with the platter's magnetic surface.

- During reading, the head detects magnetic domains (tiny magnetic regions on the platter representing zeros and ones). The magnetic signal is converted into an electrical signal and then into digital data for the computer.

- During writing, the head alters the magnetic orientation of the platter's surface to encode new binary data.

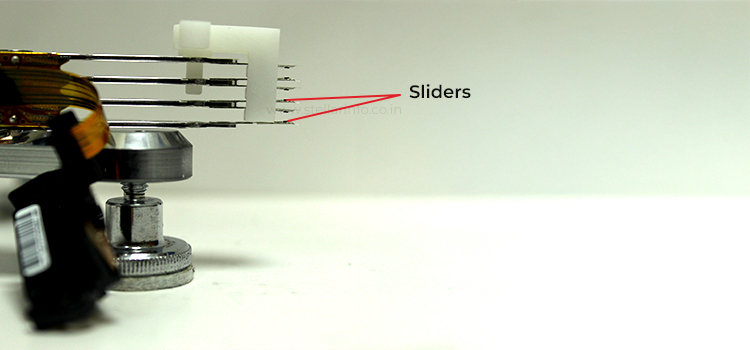

The slider, marked in the image below, plays a critical role in the functioning of the read/write head. It acts as a support structure for the head and is designed to hover just above the platter's surface.

An important concept to explore here is flying height—the extremely small distance between the read/write head and the platter. This distance is crucial for precision in read/write operations. It's incredibly small, typically between 5 to 10 nanometers. To put this in context, a human hair is about 25,000 nanometers thick. This incredibly low flying height is required for precision in reading and writing.

If the flying height were higher, it would reduce accuracy, and if lower, it would increase the risk of head crashes (where the head collides with the platter).

Given the tiny flying height, even microscopic particles of dust or oil can disrupt the head's operation or cause severe damage. To counter this,

- HDDs are equipped with recirculation filters to clean internal air; and

- breath filter prevents external contaminants from entering through the breath hole.

Now, let us examine the component responsible for controlling these precise movements and operations within the hard drive.

3. PCB

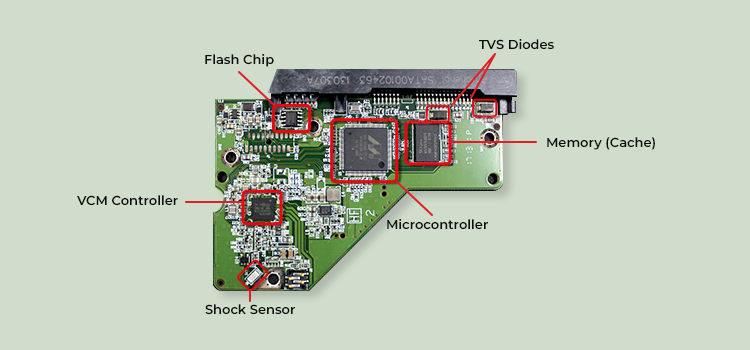

The PCB (Printed Circuit Board) is the electronic backbone of a hard drive. It controls operations and protects components.

The Printed Circuit Board (PCB) can be understood by analyzing six of its key components, each playing a vital role in the device's functionality.

- First comes the microcontroller unit—the brain of the PCB. It combines a CPU for data processing and a read-write channel to convert analog signals from the heads into digital data. It also manages data transmission via the SATA interface and oversees the hard drive's overall operations.

- The second component is memory or cache. Generally, there's a DDR SDRAM chip that stores temporary data for quick access. The memory divides into two parts: buffer/cache memory for fast data access, and firmware memory to store essential operating instructions.

- The third part is the VCM controller (Voice Coil Motor controller). It controls both the spindle motor that spins the platters and the movements of the heads for read-write operations. This is the part of the hard drive that consumes the most power.

- The fourth part is the flash chip, which has part of the firmware required for starting up and operating the hard drive. Without this firmware, the drive wouldn’t even spin up.

- The fifth part is the shock sensor. This sensor can detect vibrations or physical shocks. For instance, if the drive suffers a fall, the shock sensor automatically parks the heads to prevent platter damage.

- The sixth part is the TVS diode (Transient Voltage Suppression diode) which protects the hard drive from power surges. If a power surge occurs, the TVS diode absorbs the excess voltage and creates a short circuit to prevent further damage.

Next, we turn our attention to the mechanism that ensures the platters rotate at the exact required speeds for efficient data access.

4. Spindle

The spindle is a core mechanical part of a hard drive. Its job is to hold and spin the platters at very high speeds. This rotation is required so the read-write heads can access data from different tracks and sectors of each platter.

In old hard drives, the spindle motor was a stepper motor type with limited precision and reliability. Modern devices have advanced motors like fluid dynamic bearings or brushless DC motors. These motors offer smoother operations and are much more reliable. They also reduce noise and are less vulnerable to wear and tear.

In modern hard drives, the spindle can spin at speeds between 5,400 RPM to 7,200 RPM. Faster spindle speed allows the read/write head to reach the desired sector quickly. Some high-performance drives have RPMs reaching up to 15,000. This essentially means that in a desktop hard drive, which usually has a 3.5-inch form factor, the sectors on the outermost track of a platter move at a speed of 250 kmph!

Conclusion

By now, you should have a comprehensive understanding of the intricate workings of a hard drive.

This overview highlights the impressive technology behind hard drives. Small improvements in individual parts have contributed to the continuous evolution of hard drives. As technology advances, we can expect them to become lighter, faster, cheaper, and more reliable.

About The Author

Online Marketing Expert & Content Writer